Cutting Application

Be flexible. Deliver to every dynamic need.

Be it innovative prototypes or critical components that must pass rigorous quality testing, get your technical textiles made with the best in the business.

Cutting technology that is designed to ensure total accuracy time and again, with every single product. Digitally cutting materials for upholstery, tarps, tents, fabric architecture and even home furnishings can be delivered with remarkable productivity and give you maximum flexibility.

Create a new high bar in TechTex with superior cutting power.

Materials Used

Materials Used

- Coated textile (polyester, PVC)

- Reinforced nylon fabrics

- Silk, polyester, cotton

- Non-woven cotton or synthetics

- Acrylics

Advantages

Advantages

Precision and high speed cutting

Avoid cumbersome cardboard stencils

Optimize material yield

Enables seasonality and shorter product life cycles

Get Creative. Conquer new Markets.

World-class cutting speeds and precision now power the creation of visual signs and graphics that drives business skywards.

Our cutting technology allows for auto-trimming and contour-cutting of banners, displays, posters, flags, decals and more across your choice of materials and fabrics.

Unleash your innovative ideas for signs, graphics, displays and everything marketing.

Materials Used

Materials Used

- Corrugated, Composite boards

- Polyester fabric

- Coated textiles

- PVC & Acrylics

- Laminated & Pressure-sensitive vinyls

- Porous flexibles

Advantages

Advantages

Precision and high speed cutting

Innovative software that aids design

Avoid expensive dies

Efficient processing of fabric substrates

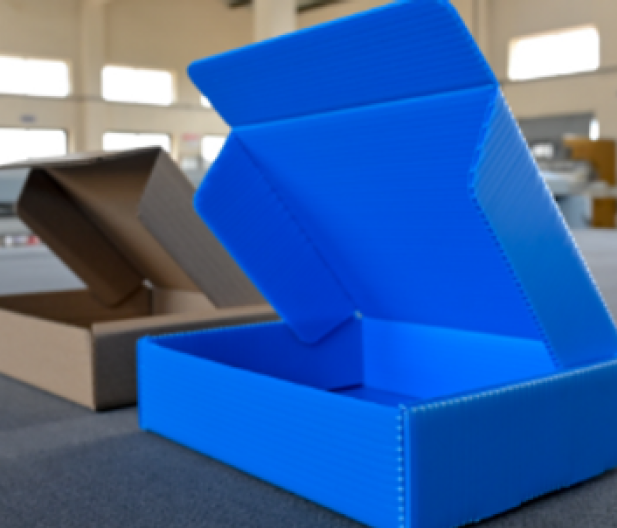

Perfect Packaging. For every Material.

Packaging is all about getting the right fit, converting the idea into reality, and experimenting with shapes and materials.

Our cutting technology allows you to create samples and modify them in a jiffy. When you are ready, roll out production of exact dimensions every single time.

Get the packaging you need, be it cardboard, foam, composite packaging, air bubble film or more!

Materials Used

Materials Used

- Corrugated Boards

- Honeycomb Boards (corrugated paper, plastic)

- Polypropylene

- Foam (EPE, EPS, PU, XLPE)

Advantages

Advantages

Minimal setup allows quick changes and iterations

Precise and efficient cutting on a digital cutting system

Delivers quality with all commonly-used packaging materials

Be Versatile. Showcase your Creatvity.

Rubber and Silicone let you explore a whole host of ideas. Whatever be your application, we can create precision cuts - be it long runs or short runs.

Our technology is ready to cut curves, edges, and straight lines, each run with perfect precision and speed.

Get the piece you need, be it silicone, latex or a variety of rubber.

Materials Used

Materials Used

- Silicone

- Latex Film

- Rubber - Natural, Solid, Foam, Sponge, Ejection

Advantages

Advantages

Allows for high degree of customization

Superior functionality, efficiency, and quality

Significantly shorten the time to market for new products

Where Custom products meet stringent Quality.

Composites serve a wide range of applications. You need the ability to create prototypes, test them, and quickly deliver long runs.

Our cutting technology lets you work with challenging materials to produce precision products, meet stringent quality tests and cater to industrial requirements.

Work with us, be it transportation, sports, automotive, wind energy or any industrial application.

Materials Used

Materials Used

- Glass Fibers

- Aramid Fibers

- Carbon Fibers

- Pre-impregnated fibers

- Polyamides

- Kevlar

Advantages

Advantages

Up to the task high-quality precision cutting solutions

Single-ply cutting equipment of choice

Flexible across a wide range of materials and cutting requirements